Industrial Blowers in Texas: How to Choose the Right System for Power, Efficiency, and Uptime

Walk into any industrial facility in Texas, from the vast petrochemical complexes lining the Houston Ship Channel to the high-speed food processors and pharmaceutical manufacturers in San Antonio and Dallas, and you’ll hear it long before you see it: the steady, powerful hum of machinery that keeps the entire plant breathing, productive, and safe.

But behind that constant, reassuring sound is an unsung, mission-critical workhorse. It is not the headline-grabbing compressors that pressurize the systems. It is not the massive pumps that move fluids.

It is the

industrial blower.

The industrial blower is the quiet engine of air movement and process stability. Its function is far more vital than simply "moving air." It is the system responsible for creating necessary vacuums, providing combustion air to burners, conveying lightweight materials, regulating critical process temperatures, removing hazardous fumes and volatile organic compounds (VOCs), stabilizing pressure, and filtering out abrasive dust and particulate matter. In essence, it is the environmental and operational regulator, ensuring the bigger, more complex machines can run continuously without overheating, choking on contaminants, or failing due to an imbalance in air flow or pressure.

And nowhere is this role more crucial than in a state like Texas. Here, the unique confluence of high ambient temperatures, relentless dust storms, proximity to the coast (bringing humidity and corrosive elements), and the demanding, 24/7 production schedules of energy and manufacturing sectors can punish equipment mercilessly. In this environment, your blower isn’t just a component in a larger system; it is the guardian of uptime. A failure in this single piece of machinery can trigger a cascading shutdown, impacting everything from safety compliance to production quotas.

At TNT Industrial, we've accumulated decades of field experience observing the consequences of poorly managed air systems. We’ve seen firsthand what happens when a blower is undersized for a high-temperature application, installed with inadequate vibration isolation, or pushed beyond its defined performance envelope in a corrosive atmosphere. The immediate and long-term cost is astronomical: it’s not just a few hours of downtime, but significant lost output, catastrophic damage to expensive ancillary equipment (like motors and filtration units), and safety risks, including the potential for combustible dust ignition, that ripple through the entire facility’s risk profile.

This blog is designed to be a grounded, engineering-backed resource for Texas facilities managers and engineers. It offers a comprehensive guide to selecting, sizing, and maintaining the right industrial blower system, be it a centrifugal, positive displacement, or regenerative model. This advice is built on practical insights derived from rigorous industry research, successful installations across the state, and, perhaps most importantly, real-world equipment failures that taught us the most valuable, and often painful, lessons about efficiency, power, and long-term reliability.

Why Industrial Blowers Play a Bigger Role in Texas Facilities Than You Think

The Texas Climate Changes the Requirements

High heat.

High dust loads.

High production volumes.

Texas is a tough environment for any air-handling equipment. Industrial blowers often work harder here than in cooler states, simply because they need to compensate for environmental stress. According to data from the U.S. Department of Energy, improperly sized or poorly maintained air movement systems can increase total plant energy use significantly, especially under heat and load conditions typical in Texas. When a blower is undersized or built with the wrong materials for harsh Texas environments, you’ll see:

- Decreased airflow output

- Excessive motor temperatures

- Vibration and bearing failure

- Premature fan wheel wear

- Inconsistent pressure delivery

These aren’t minor issues; they directly affect production uptime.

Centrifugal, Regenerative, or High-CFM? Choosing the Right Blower Type

There’s no such thing as “one-size-fits-all” in industrial blowers. Texas facilities, known for their diverse and demanding industrial landscape, rely on several distinct blower types, each engineered for specific performance characteristics, depending on the application at hand. Selecting the wrong type can lead to astronomical energy bills, inadequate process control, and costly downtime.

The three primary categories of industrial blowers typically utilized in Texas operations are:

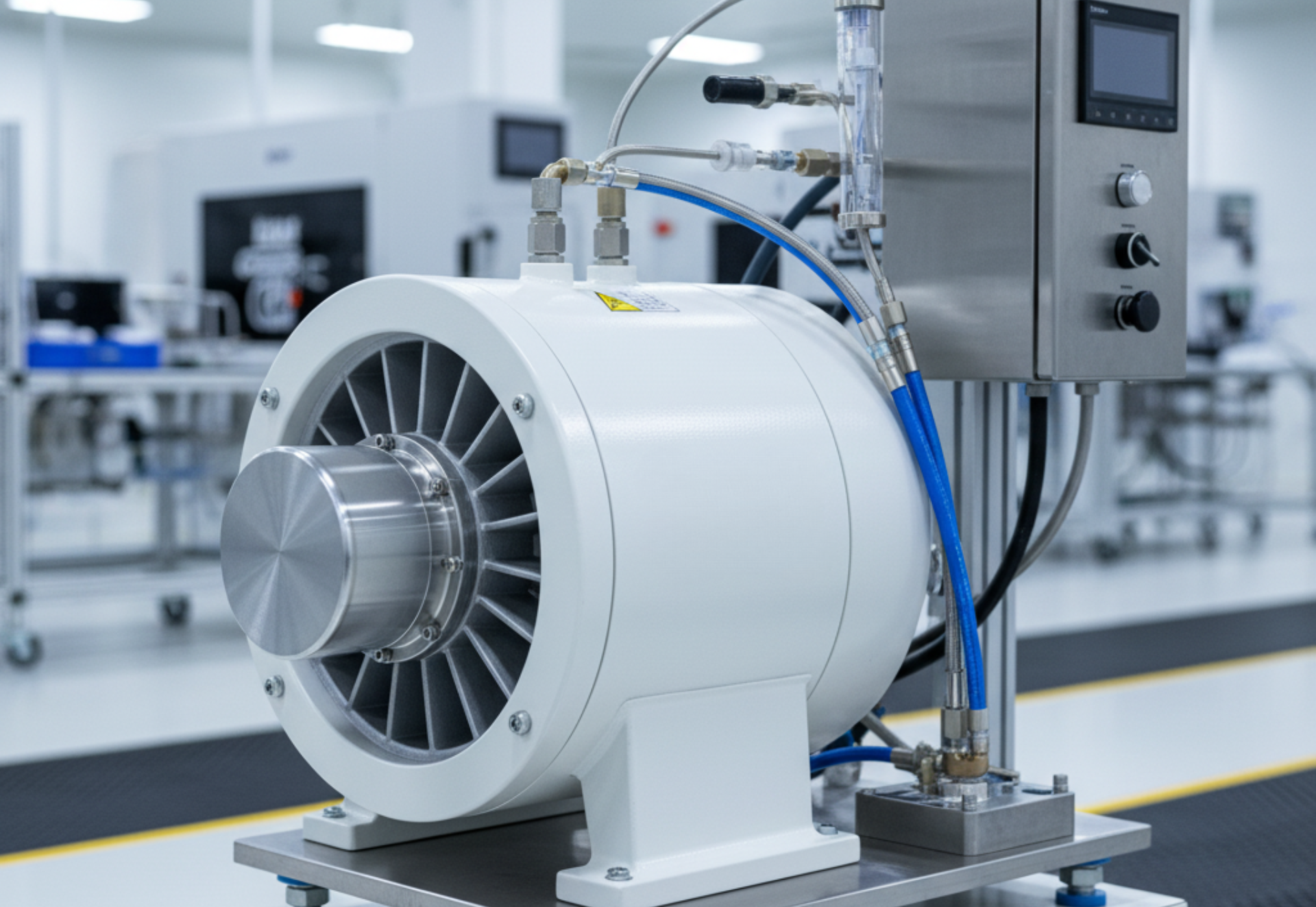

- Centrifugal Blowers (The Workhorse): These are perhaps the most common, operating much like a squirrel cage fan to move large volumes of air or gas at low to moderate pressures. They are highly efficient for continuous, high-volume flow applications such as ventilation, dust collection, material conveyance, and aeration in wastewater treatment. Their robust design allows for reliable, long-term operation.

- Regenerative Blowers (The Compact Solution): Often called side-channel blowers, these systems are excellent for creating low-pressure or medium-vacuum air streams. They are characterized by a non-positive displacement design that creates a unique air-pumping action, ideal for pneumatic tube systems, packaging machinery, small-scale drying operations, and holding/lifting applications where clean, oil-free air is a necessity. Their compact size and low maintenance requirements make them a favorite for installations with spatial constraints.

- High-CFM Blowers (The Powerhouse): These are specialized systems, sometimes a subset of centrifugal blowers, but designed specifically to move extremely high Cubic Feet per Minute (CFM) volumes. They are critical in large-scale applications such as forced draft, induced draft in power generation, large combustion air systems, and substantial air pollution control operations (scrubbers, oxidizers) where massive airflow is required to maintain system integrity and compliance.

The decision hinges on a detailed evaluation of three core performance metrics: Flow (CFM), Pressure/Vacuum (PSI/in. H2O), and Temperature (F/C). A Texas facility's decision must meticulously balance these factors to ensure optimal power consumption, process efficiency, and, most critically, operational uptime.

1. Centrifugal Blowers

Best for: High-pressure applications, dust collection, and ventilation under load. Centrifugal blowers are the most widely used industrial blower across Texas because they deliver stable airflow even under restrictive or dirty conditions. They excel in:

- Manufacturing plants

- Cement and aggregate facilities

- Metal fabrication environments

- Petrochemical processing

Research says that centrifugal blowers maintain higher efficiency at varying pressures compared to many other blower types (Based on the research of Engineering Toolbox).

2. Regenerative (Side-Channel) Blowers

Best for: Continuous, oil-free airflow in clean environments.

Often used in:

- Electronics manufacturing

- Food packaging

- Pneumatic conveying

- Wastewater aeration

Regenerative blowers are compact, quiet, and reliable. They don’t produce high pressures like centrifugal units, but their simplicity makes them nearly maintenance-free.

3. High-CFM Industrial Blowers

Best for: Large-scale ventilation, cooling, drying, and large open industrial spaces.

These blowers focus on

volume rather than pressure, ideal for Texas plants that must move a lot of hot air out quickly.

Examples include:

- Grain storage facilities

- Large warehouses

- Fabrication bays

- Foundries

According to airflow studies from the Occupational Safety & Health Administration (OSHA), proper ventilation significantly improves worker safety and reduces airborne contaminants (External reference: osha.gov).

Key Factors Texas Facilities Should Consider When Choosing an Industrial Blower

Choosing a blower isn’t just about airflow; it's a critical engineering decision that profoundly impacts operational efficiency, energy consumption, and system longevity in the challenging Texas industrial climate. It’s about understanding your environment, load, application, and future needs to ensure peak performance and minimal downtime. Here’s what matters most:

1. Airflow Requirements (CFM - Cubic Feet per Minute)

The required CFM is the foundational specification for any industrial blower system. It is a direct measure of the volume of air that must be moved through your system to achieve the desired process outcome, whether it's conveying material, providing aeration, cooling, or ventilation.

- System Analysis: Accurate CFM calculation demands a thorough review of your plant layout, the diameter and length of all associated ducting, the pressure drop across equipment (like filters or nozzles), and the specific process airflow requirements.

- The Goldilocks Principle: Undersizing a blower will starve the system, leading to inefficient processes, product quality issues, excessive heat buildup, or failure to meet regulatory standards. Conversely, oversizing a blower results in unnecessary capital expenditure, excessive noise, and, most importantly, a significant waste of energy through operating a unit well below its peak efficiency curve. The goal is to select a unit that meets the maximum required CFM while having a small buffer for future expansion or unforeseen system resistance.

2. Static Pressure (SP)

Static pressure is the resistance the blower must overcome to push or pull air through the system. It is the measure of potential energy stored in the compressed air within the ductwork.

- Resistance Sources: In Texas facilities, common sources of high static pressure include intricate or long duct runs, sharp elbows, multiple fittings, dust collectors with high-efficiency filters, silencers, heat exchangers, and restrictive process nozzles.

- Impact on Performance: A blower must be explicitly rated to maintain the required CFM at the calculated maximum static pressure. If the resistance (SP) exceeds the blower's capability, the actual airflow (CFM) will drop significantly below the required level, severely compromising the entire process. This is particularly critical in applications like pneumatic conveying, where a precise balance of pressure and flow is necessary to keep materials moving.

3. Blower Type and Technology

The operating principle of the blower heavily influences its efficiency, noise profile, maintenance needs, and ideal application range.

- Positive Displacement (PD) Blowers: These are ideal for high-pressure applications (up to 15 PSIG) and moderate-to-low CFM requirements. PD blowers deliver a constant volume of air regardless of varying downstream resistance. They are commonly used in wastewater treatment (aeration), pneumatic conveying, and gas boosting. They are generally rugged but require precise timing gear maintenance.

- Centrifugal Blowers: These are best suited for high-CFM applications at low-to-moderate pressures (up to 3 PSIG). They operate by increasing the kinetic energy of the air through an impeller and then converting it to static pressure. They are highly efficient when operating at their design point and are favored for general ventilation, air movement, and fume exhaust.

4. Energy Efficiency and Operating Costs (Life Cycle Cost)

Given the high cost of industrial electricity in Texas, the blower’s energy consumption is often the single largest factor in its total life cycle cost.

- Wire-to-Air Efficiency: A highly efficient blower converts electrical energy into useful air power with minimal loss as heat or vibration. When comparing models, always focus on the "wire-to-air" efficiency curve to ensure the blower is operating near its peak efficiency at your facility's specific CFM and SP requirement.

- Variable Speed Drives (VSDs/VFDs): Implementing a Variable Frequency Drive (VFD) is crucial for applications with fluctuating airflow needs. VFDs allow the motor speed to be adjusted, resulting in massive energy savings (often following a cubic relationship—a 20% speed reduction can mean a nearly 50% energy reduction). This is a vital component for maximizing energy savings and system flexibility.

5. Environmental and Operational Factors

Texas facilities face unique environmental challenges that must be addressed in the blower selection process.

- Temperature and Humidity: High ambient temperatures can reduce air density, which affects the blower's performance and cooling needs. The blower and motor must be rated for continuous operation in high-heat environments.

- Noise Abatement: Many industrial areas have strict noise ordinances. Blower systems, especially high-speed or PD units, can generate significant noise. Consideration must be given to installing silencers, acoustic enclosures, or selecting low-noise models to comply with regulations and protect worker health.

- Filtration and Air Quality: If the air is dusty, corrosive, or contains particulates, the blower and its inlet components must be protected with appropriate industrial-grade filters. The material of construction (e.g., carbon steel vs. stainless steel) must be compatible with the process medium to prevent corrosion and premature failure.

6. Temperature Tolerance

Texas heat pushes equipment to its limits. You need:

- Heat-resistant bearings

- Correct motor insulation class

- Proper cooling paths

- High-temperature fan wheels

7. Energy Efficiency

Energy-efficient blowers reduce operational cost and heat output, which is crucial in Texas facilities already battling ambient temperatures.

A study from ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) highlights how correctly sized airflow systems dramatically reduce energy waste.

8. Material Durability

For harsh environments, consider:

- Stainless steel construction

- Corrosion-resistant coatings

- Heavy-duty bearings

- Sealed housings for dust exclusion

Facilities near coastal Texas (Corpus Christi, Galveston) often need corrosion-resistant materials because salt accelerates blower degradation.

9. Noise Requirements

Oil & gas facilities, food production plants, and manufacturing sites often need noise-dampened solutions for worker protection.

Common Mistakes Texas Facilities Make When

Buying Industrial Blowers

Having inspected hundreds of blower systems across Texas, we’ve seen the same patterns repeat:

Buying based on price instead of duty cycle

Low-cost blowers burn out fast under Texas workloads.

Ignoring how the duct layout affects performance

Even the best blower can’t overcome bad duct design.

Skipping vibration analysis

Leads to misalignment, bearing failure, and downtime.

Underestimating Texas heat

Blowers rated for 90°F ambient WILL fail when your factory hits 110°F.

Not planning maintenance access

If a blower is buried behind equipment, it will never be maintained properly.

Why Partnering With a Texas-Based Industrial Air Specialist Matters

A blower purchased online won’t account for:

- Your plant environment

- Your heat profile

- Your dust levels

- Your production schedule

- Your airflow needs

Industrial Air Services LLC. doesn’t guess; we engineer solutions.

We assess the facility, airflow requirements, energy demands, and future capacity. Then we pair you with the correct blower system, install it correctly, and maintain it for long-term reliability.

That’s the difference between equipment

And an engineered solution built for uptime.

How TNT Supports Industrial Blower Systems Across Texas

We provide:

- Industrial blower consultation

- Correct system sizing

- Blower installations

- Preventive maintenance

- Vibration and alignment checks

- Repairs and emergency service

- High-performance replacements

We handle blowers from:

- Manufacturing

- Oil & gas

- Plastics

- Food production

- Agriculture

- Chemical facilities

- Warehousing

- Metal fabrication

- Medical

If your facility moves air, we support it.

Final Thoughts: In Texas, the Right Blower Protects Your Entire Operation

An industrial blower isn’t a commodity; it’s a performance-critical component.

The right system improves:

- Airflow consistency

- Energy efficiency

- Worker safety

- Equipment lifespan

- Total plant uptime

The wrong system?

It quietly becomes the most expensive mistake in your operation.

With the heat, dust, and demands of Texas industry, your blower must be engineered, not just purchased.

Upgrade Your Industrial Blower System in Texas?

Industrial Air Services IAS. provides engineered blower solutions designed for uptime.

From sizing to installation to preventive maintenance, we make sure your facility gets the power, airflow, and reliability it needs.

Contact

Industrial Air Services IAS today to schedule a consultation.

Let’s build a blower system that keeps your Texas plant running strong.

FAQs

1. Can you leave an industrial fan on all night?

Yes, as long as the industrial blower or ventilation fan is rated for continuous duty and properly maintained. Many Texas facilities run blowers 24/7 for cooling, ventilation, dust control, or process air movement. The key is ensuring the system has:

- the correct motor insulation class

- proper cooling

- vibration-free mounting

- regular maintenance

If you are unsure whether your current blower is safe for continuous operation, Industrial Air Services IAS can inspect, size, and optimise your industrial blower system to prevent overheating or premature failure. Learn more about our engineered blower solutions at IAS.

2. How many CFM is a good blower?

It depends entirely on your application.

For example:

- Ventilation may require 2,000–10,000+ CFM

- dust collection may require 1,200–4,500 CFM per machine

- Process air systems may need precisely engineered CFM based on ducting and static pressure

A “good” blower is one whose CFM matches the facility’s airflow demand without wasting energy or sacrificing pressure. Undersized blowers reduce performance. Oversized blowers waste electricity.

If you want exact CFM recommendations for your facility, IAS provides engineered airflow assessments and blower sizing services to ensure your Texas operation gets the right blower for uptime and efficiency. Visit IAS for professional guidance.

3. What is the most efficient type of blower?

For industrial applications, centrifugal blowers are often considered the most efficient — especially in systems that require stable airflow under varying static pressures. They deliver strong performance, lower noise, and better efficiency in high-demand environments.

However, regenerative blowers can also be highly efficient for clean-air, oil-free, low-pressure applications. The “most efficient” blower always depends on:

- pressure requirements

- CFM demand

- temperature conditions

- duct layout

- runtime and duty cycle

Industrial Air Services engineers evaluate your complete system and recommend the most energy-efficient blower based on real operating conditions, not generic ratings. Whether you need centrifugal, regenerative, or high-CFM solutions, IAS provides professional blower selection, installation, and maintenance. Get started at IAS.