Why Partnering With a Certified Zeks Air Dryer Distributor Protects Your Entire Compressed Air System

Walk into any industrial facility and you’ll see compressed air everywhere, powering tools, driving automation, cleaning product lines, supporting packaging equipment, or keeping pneumatic systems moving with precision.

But what makes compressed air

usable isn’t the compressor.

And it isn’t the storage tank.

It’s something far more overlooked:

The air dryer.

In Texas facilities, especially those operating in high-humidity or heat-heavy environments, moisture becomes a silent saboteur. If not removed properly, water vapor infiltrates every corner of the compressed air system, corroding piping, ruining valves, sticking actuators, contaminating products, and forcing compressors to work harder than designed.

That’s why partnering with a certified Zeks air dryer distributor isn’t just about product availability. It’s about protecting uptime, extending equipment life, and ensuring your compressed air system meets the quality standards your facility depends on.

At IndustrialAir Services IAS, we see the consequences of improper drying every week. Flooded lines. Failed pneumatic actuators. Saturated filters. Rust-filled piping. And behind almost every failure is the same root cause:

an air dryer system that wasn’t sized correctly, maintained properly, or designed with real-world Texas conditions in mind.

This blog cuts through the noise and gives you a clear, engineering-backed guide to Zek's air dryers and why working with a certified distributor makes the difference between a reliable air system and one constantly fighting moisture-related downtime.

Compressed Air Without Proper Drying: A Hidden Threat to Texas Facilities

Texas is humid.

Texas is hot.

And both conditions dramatically increase water load inside compressed air systems.

Here’s why:

When a compressor pulls in hot, humid air, it pressurizes it, and pressure increases the concentration of water vapor. That vapor condenses as the air cools downstream, leading to:

- water pooling inside tanks

- corrosion inside valves

- blown-out seals

- clogged filters

- contaminated final products

- Higher energy consumption

- catastrophic system failure

According to Engineering Toolbox, compressed air at 100°F holds twice the moisture of air at 70°F, meaning Texas facilities start with a moisture disadvantage the moment the compressor kicks on.

Without a properly sized Zeks dryer, moisture becomes unavoidable.

Why Zeks Air Dryers Are Trusted Across Industrial Applications

Zeks has earned a strong reputation because their systems don’t just “dry air”, they stabilize an entire compressed air environment.

Here are the core reasons Zeks stands out:

1. Stable Dew Point Control

Zeks dryers consistently maintain the correct dew point, ensuring moisture doesn’t condense downstream, even during load spikes.

2. Energy-Efficient Performance

With heatless, heated purge, cycling, and non-cycling options, Zeks designs dryers that help reduce operational cost without sacrificing performance.

3. Designed for Demanding Conditions

Texas heat, fluctuating humidity, and long operational hours punish low-quality dryers. Zeks systems are engineered for high-duty cycles and harsh environments.

4. Long-Term Reliability

With robust internal components, high-quality desiccant, and intelligent control systems, Zeks dryers deliver durability that minimizes unplanned shutdowns.

5. Complete Moisture Management

Depending on the application, Zeks dryers can remove:

- water vapor

- aerosols

- oils

- particulates

This makes them ideal for food, manufacturing, petrochemical, energy, plastics, and packaging facilities.

And according to the

Compressed Air & Gas Institute (CAGI), even small amounts of water vapor dramatically reduce pneumatic component life, increasing maintenance costs.

Understanding Zeks Dryer Types: Which One Does Texas Need?

Different industries need different types of drying. Here’s how each Zeks system is designed to perform.

Selecting the right compressed air dryer is not a one-size-fits-all decision; it is a critical component of maintaining the health and efficiency of your entire compressed air system. Different industries and applications demand varying levels of air purity and dew point. The diverse climate and industrial needs of a state like Texas, ranging from petrochemical plants on the coast to manufacturing in the central region, necessitate a careful examination of Zeks' robust dryer portfolio.

Here's a breakdown of how each Zeks system is expertly designed to perform, ensuring you achieve the specific drying performance your operation requires:

| Zeks Dryer Type | Principle of Operation | Key Benefits | Best Suited For |

|---|---|---|---|

| Refrigerated Air Dryers | Cools the compressed air, causing water vapor to condense into liquid, which is then separated and drained. | Cools the compressed air, causing water vapor to condense into liquid, which is then separated and drained. Low initial cost, minimal maintenance, simple operation, and consistent performance for a +38°F pressure dew point. | General manufacturing, automotive repair, woodworking, and applications where air lines are not exposed to freezing temperatures. Ideal for many Texas-based light industrial facilities. |

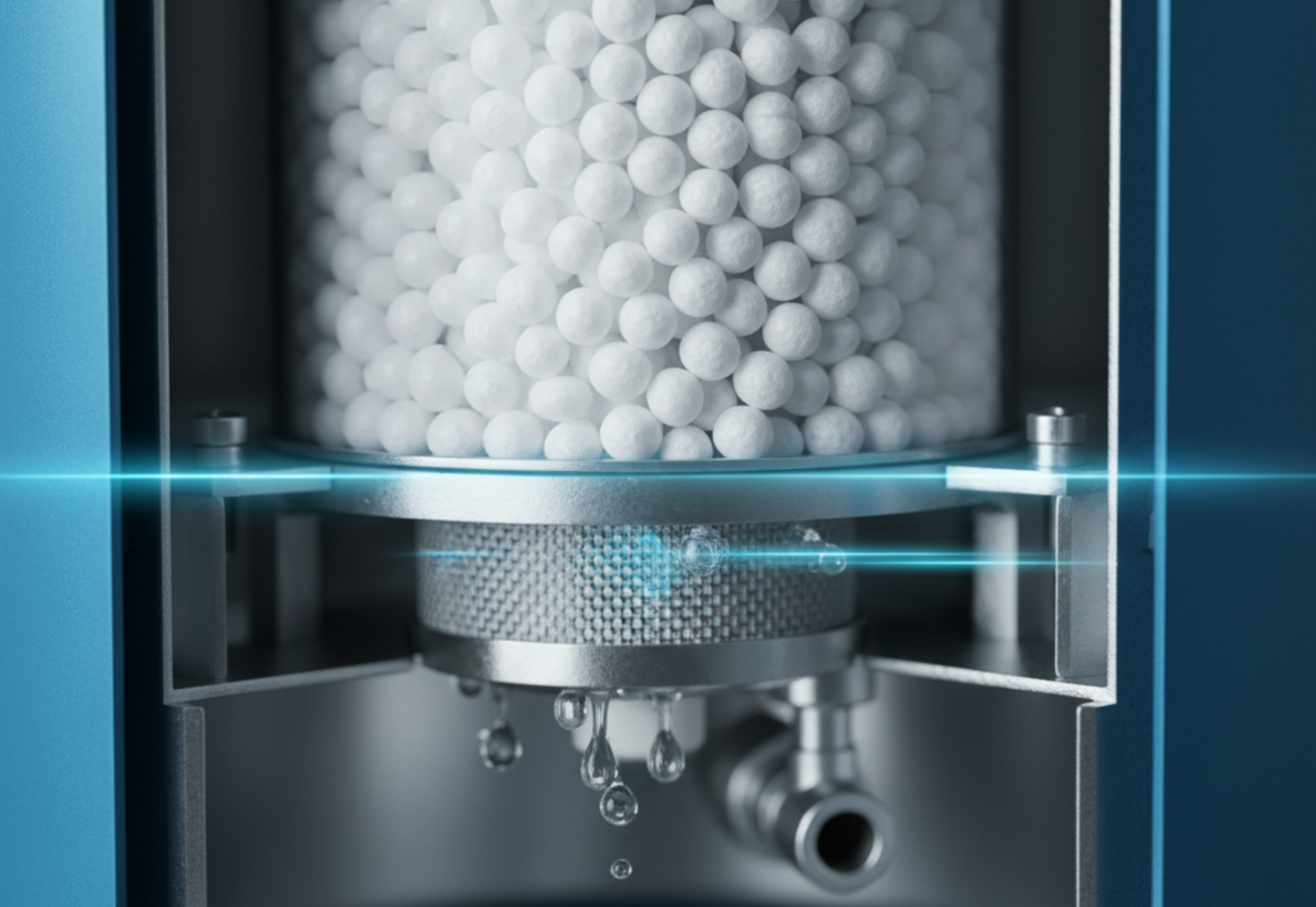

| Desiccant (Adsorption) Air Dryers | Utilizes an adsorbent material (like activated alumina or molecular sieve) to chemically attract and hold water vapor. The media is then regenerated (either via heat or a purge of dry air). | Achieves extremely low dew points (typically -40°F or lower), crucial for protecting sensitive equipment and processes. | Petrochemical, food and beverage, pharmaceutical manufacturing, electronics, and any application requiring critical purity and freeze protection. Essential for sensitive instrumentation and outdoor lines in potentially freezing regions. |

| Cycling Refrigerated Dryers | A variation of the standard refrigerated dryer that uses a thermal storage medium (like glycol) and cycles the compressor on and off based on demand, rather than running continuously. | Significant energy savings (up to 80% in low-demand situations), excellent part-load efficiency, and a stable pressure dew point. | Operations with fluctuating air demand, or facilities focused on maximizing energy efficiency and minimizing operational costs. |

| High-Temperature Dryers | Designed to handle high-temperature discharge air directly from an air compressor without the need for an external aftercooler | Space-saving, reduces installation complexity, and simplifies the overall system design. | Small to medium-sized piston or rotary screw compressor systems where a dedicated aftercooler is not practical or desired. |

Choosing the appropriate Zeks dryer, whether a simple, cost-effective refrigerated model for general use or a high-performance desiccant dryer for critical, moisture-sensitive processes, is the first and most important step in protecting your air tools, pneumatic equipment, and final products from the damaging effects of water contamination.

Why “Buying a Zeks Dryer Online” Is Not the Same as Working With a Certified Distributor

Many facilities make the same mistake: They buy based on price, not performance requirements.

But compressed air drying is highly technical, and choosing the wrong dryer leads to:

- Incorrect dew point

- upstream flooding

- oversaturated desiccant

- higher purge-air use

- energy waste

- early failure

A certified Zeks distributor like IAS ensures:

✔ correct sizing

✔ correct dew point selection

✔ correct installation

✔ correct inlet and ambient temperature planning

✔ correct air filtration

✔ correct flow and load analysis

✔ correct maintenance program

This is engineering, not e-commerce.

What IAS Does as a Certified Zeks Air Dryer Distributor

We don’t just sell equipment.

We design complete end-to-end systems engineered for uptime.

IAS provides:

- Compressed air audits

- Dew point analysis

- Load cycling assessments

- Energy-efficiency evaluations

- Correct dryer sizing

- Zek's system installation

- Filtration and condensate management

- Desiccant replacement

- Preventive maintenance

- 24/7 emergency response

And because we work across Texas’s major industries, our teams understand the environmental pressures that many online retailers simply can’t factor into a one-size-fits-all purchase.

Case Scenario: What Happens When You Use the Wrong Air Dryer?

A packaging plant in Central Texas recently reached out after dealing with constant line shutdowns. Sensors were failing. Cylinders stuck midway through cycles. Their labeling machines misprinted dozens of runs per shift.

Their existing dryer was rated for 100 SCFM.

Their actual system required 180 SCFM.

When we installed a Zeks refrigerated dryer matched to their real load, moisture dropped instantly, and their pneumatic failure rate fell by 87% within 30 days.

That’s what engineering-based selection delivers.

Signs Your Facility Needs a Better Air Dryer ASAP

If you’re experiencing any of these issues, your dryer may be undersized or failing:

- Water in the air lines

- Rust at fittings

- Saturated drain traps

- Sluggish pneumatic cylinders

- Clogged filters

- Unexpected pressure drops

- Oil/water mix in the downstream tools

- Frequent desiccant replacement

In Texas humidity, these symptoms escalate quickly, especially during summer.

The IAS Difference: Local Expertise, Engineering Accuracy

Texas facilities have unique demands:

- High ambient temperatures

- Long duty cycles

- Extreme humidity

- Sensitive applications

- Compressed air quality requirements

- Seasonal environmental changes

IAS understands these conditions at a system level.

We don’t “sell Zeks.”

We engineer solutions that last.

The Right Zeks Air Dryer Protects More Than Air Quality; It Protects Uptime

A compressed air system is only as reliable as its drying system.

You can invest in the most advanced compressor in the world, but if moisture penetrates your lines, everything downstream is at risk: tools, valves, actuators, sensors, and even finished product integrity.

A certified Zeks distributor ensures:

- Correct design

- Correct sizing

- Correct installation

- Correct lifecycle support

In Texas, with its heat and humidity, that expertise isn’t optional, it’s the difference between a reliable operation and one constantly fighting moisture-related failures.

Protect Your Compressed Air System With Zeks?

Industrial Air Services IAS is your certified Zeks air dryer distributor in Texas.

We engineer moisture-control systems that maximize uptime, energy efficiency, and air quality, no guessing, no shortcuts.

Visit our nearest branch, San Antonio: 210-255-1441, Austin: 512-243-2277, and Houston today to schedule a compressed air assessment or email us at sales@iastx.com.

Let’s build an air drying system engineered for Texas conditions.

FAQs

1. Is it cheaper to repair or replace a dryer?

It depends on the age, condition, and efficiency of the air dryer.

If the dryer is under 7–10 years old and the issue is limited to drains, sensors, or minor component wear, repairs are usually cost-effective. But if the dryer is:

- undersized for the application

- consuming excess energy

- failing frequently

- corroded internally

- unable to maintain the dew point

Then replacing it with a newer, more efficient model (like a Zeks refrigerated or desiccant dryer) typically saves more money long-term.

IAS provides full diagnostics, repair recommendations, and replacement guidance to help you decide the most cost-effective approach. Whether you need repair, service, or a new Zeks air dryer, IAS is your trusted Texas provider.

2. What brand of dryer has the fewest problems?

Zeks is widely recognized as one of the most reliable compressed air dryer brands in the industry because of:

- stable dew point control

- durable internal components

- energy-efficient operation

- high-duty-cycle performance

- dependable moisture removal

Their refrigerated and desiccant dryers consistently show lower failure rates when correctly sized and maintained.

As a certified Zeks distributor, Industrial Air Services IAS delivers authorized equipment, installation, and professional maintenance, ensuring your dryer performs with maximum uptime and minimal issues.

3. How much air does a desiccant dryer consume?

Most heatless desiccant air dryers consume

10%–20% of the rated airflow as purge air. Some heated purge and blower purge models consume less, depending on the design and duty cycle.

Your actual purge-air consumption depends on:

- dryer size

- operating pressure

- inlet moisture load

- ambient temperature

- dew point requirements

Choosing the wrong dryer can dramatically increase air and energy consumption. IAS engineers evaluate your system and match you with the right Zeks desiccant dryer to minimize purge loss and reduce operating cost.

For purification planning, airflow calculations, and engineered moisture-control systems.