ACCESSORIES

At Industrial Air Services (IAS), we recognize that reliable accessories are crucial to maintaining the optimal performance of your compressed air and vacuum systems. Our full line of accessories—from filters and mist eliminators to drains and air receivers—is designed to enhance efficiency, minimize downtime, and prolong the life of your equipment. By integrating the right accessories into your system, you can lower operating costs, ensure cleaner air output, and protect your investment for years to come.

Air/Oil Separators, Filters, Silencers

Mist Eliminators

Our mist eliminators provide high-efficiency filtration that removes oil, water aerosols, and fine particulates from your compressed air stream. With service lives that exceed 10 years and minimal pressure drop, these units deliver reliable protection at a cost-effective price point. Whether you operate a small shop or a large industrial facility, mist eliminators help safeguard your equipment and maintain consistent air quality.

Air/Oil Separators, Filters, Silencers

Filters

IASTX offers a wide range of compressed air filters engineered for clean, oil-free, and moisture-free air. With multiple element grades available, these filters can handle diverse applications—from manufacturing to medical. Their durable construction ensures long-term use, while space-saving designs make maintenance fast and simple. By reducing contaminants, our filters help extend the lifespan of your system and improve energy efficiency.

Highlighted Features:

Improved filtration for compressor room or point of use application

Reliable and efficient liquid and pasrticulate removal

Space saving design – no tie rod allows easy bowl removal

Five (5) element grades ranging from 25 to 0.01 micron

Nineteen (19) models ranging from 8 to 1500 scfm at 100 psig

Comprehensive range of compressed air filter accessories

Reliability is built in… and backed by a 1 year element and a 10 year housing warranty!

Condensate Management Systems

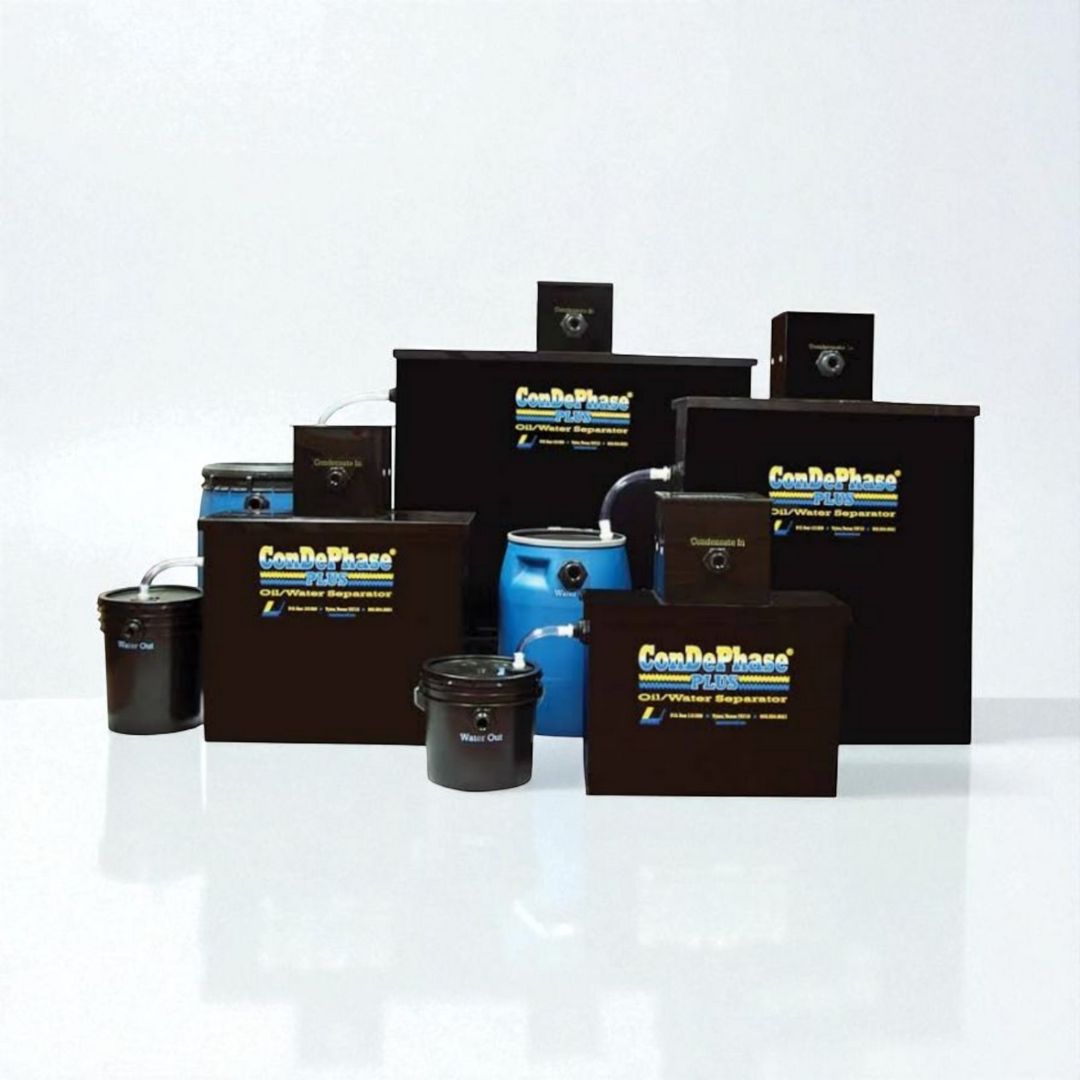

Oil/Water Separators

Condensate management is critical to system health. Our oil/water separators provide an environmentally safe method to dispose of compressor condensate without costly treatment. Paired with pneumatic or timed drains, your system remains free of unwanted moisture buildup. These solutions reduce corrosion, prevent costly breakdowns, and comply with environmental standards.

Condensate Management Systems

Pneumatic/Mechanical Drains

Our pneumatic and mechanical drains are designed for reliability and efficiency in compressed air systems. The large bowl capacity and quiet zone design ensure liquids are effectively separated, preventing re-entrainment into the air stream. Built with durable metal construction, these drains are fully compatible with all compressor lubricants and perform seamlessly in systems up to 200 psig.

Highlighted Features:

Maximum fluid temperature: 175°F

Maximum operating pressure: 200 psig

No air loss drain

Manual override option – drain on demand

Float type operation – no electricity needed

Condensate Management Systems

Electric Timed Drains

The electric timed drain offers precise, automatic condensate removal for a wide range of applications. Featuring a dual timer, it allows users to customize drain cycles with accuracy, reducing wasted air and preventing moisture buildup. This adaptability ensures maximum efficiency and protection for compressed air systems.

Highlighted Features:

NEMA 4 motor

Dual timing adjustments

Indoor/outdoor application

Manual Push to test button

Indicating lights of valve position open or closed

High temperature applications

Reliable operation

Versatility in installations

Air Receivers / Tank

Air Receivers

Air receivers act as storage tanks, maintaining consistent pressure during high-demand periods. By reducing compressor cycling, they improve efficiency and lower energy costs. Our receivers are available in multiple sizes and meet industry safety standards to provide lasting performance.