Why Aluminum Compressed-Air Piping Delivers Long-Term Value: Benefits, ROI & Installation Guide

Why the Right Piping System Matters

In any industrial or commercial setting that relies on compressed air, the network of pipes transporting that air is just as critical as the compressor itself. Often overlooked, the piping system's design, material, and maintenance directly impact the overall efficiency, reliability, and cost-effectiveness of the entire compressed-air operation. Poorly designed, inadequately installed, or corroded pipes are a significant drain on resources, leading to a cascade of problems, including leaks, significant pressure drops, and contamination. These issues not only compromise the quality of the compressed air but also result in substantial energy waste and increased operational expenses.

Indeed, the financial implications of a subpar piping system can be staggering. According to authoritative sources like

Plant Engineering, a leading publication for industrial professionals, air leaks alone can account for an astonishing up to 30% of total compressed-air energy loss. To put this into perspective, for many facilities, this translates to thousands, if not tens of thousands, of dollars in wasted electricity every single year. This inefficiency is a direct hit to the bottom line. Choosing piping material and system design is a critical business decision, not just an engineering one.

Recognizing these inefficiencies and the need for more robust, cost-effective solutions, an increasing number of industrial facilities, particularly across Texas, are making a strategic shift. They are actively replacing outdated and less efficient piping materials, such as traditional steel or PVC lines, with aluminum compressed-air piping. This modern solution stands out due to its unique combination of benefits: it is remarkably lightweight, inherently leak-resistant, and significantly more durable. By adopting aluminum piping, these facilities are not just upgrading a component; they are fundamentally improving their system's efficiency, enhancing overall reliability, ensuring superior air quality, and ultimately, realizing substantial long-term value.

At the forefront of this crucial industry transition, companies like Industrial Air Services Texas (IAS) have established themselves as leaders. IAS has been instrumental in designing and installing high-performance compressed-air systems that leverage the advantages of aluminum piping. Their expertise serves a diverse range of critical sectors, including manufacturing plants, medical facilities, and various commercial enterprises throughout the entire state of Texas. Their commitment to utilizing advanced solutions like aluminum piping underscores the significant benefits it offers in optimizing compressed air operations for demanding industrial applications.

What Is Aluminum Compressed-Air Piping?

Aluminum piping is a modular, corrosion-resistant system specifically engineered for the efficient and reliable transport of compressed air. This innovative system is designed to deliver compressed air from the main compressor unit to various workstations, machinery, and pneumatic tools throughout an industrial facility.

Unlike traditional piping materials such as black-iron or galvanized steel, aluminum pipes boast

smooth inner surfaces. This crucial feature plays a significant role in minimizing pressure drop across the system, ensuring that compressed air reaches its destination with optimal force and volume. Furthermore, the inherent properties of aluminum prevent the formation of rust, scale, or other corrosive byproducts that are common with older piping technologies. The cumulative result of these advantages is a consistent and stable airflow, leading to higher-quality compressed air that improves the performance and longevity of pneumatic equipment.

At IAS, we leverage cutting-edge aluminum piping technologies that are widely compatible with most industrial air compressors and their associated accessories. This broad compatibility makes our aluminum piping solutions exceptionally versatile and ideal for a variety of applications. Whether you are planning a new installation for a brand-new facility or undertaking retrofit upgrades to modernize an existing compressed air network, aluminum piping offers a superior, long-term solution. Its modular design also simplifies installation and future modifications, contributing to reduced labor costs and minimal downtime.

The Key Benefits of Aluminum Piping Systems

1. Corrosion-Free and Clean Air

Steel and galvanized piping corrode over time, flaking rust into the airflow. That rust contaminates equipment, paint finishes, and pneumatic tools.

Aluminum, by contrast, is naturally oxidation-resistant. The smooth, non-reactive inner layer keeps air clean, vital for medical, food, and pharmaceutical operations that require ISO 8573-1 purity levels.

2. Leak-Free Connections

Traditional threaded fittings often loosen with vibration, creating small leaks that add up to big losses.

Modern aluminum systems use push-to-connect or compression fittings that create a secure, airtight seal. IAS technicians are trained to assemble these fittings for long-term reliability, ensuring every joint is leak-tested before commissioning.

3. Lightweight and Easy to Install

Aluminum weighs about

one-third as much as steel, which means faster installation and easier handling. Crews can install or reroute lines without heavy lifting gear or welding.

This reduces labor hours and downtime, especially useful for facilities expanding production lines or adding new machines.

4. Low Pressure Drop = Energy Savings

Smooth internal surfaces and straight-through fittings minimize friction losses. That means your compressor doesn’t have to work as hard to maintain target PSI, directly reducing electricity consumption.

IAS customers have reported 10–18 % energy reductions after switching to aluminum piping systems, particularly when paired with variable-speed compressors and air dryers.

5. Scalable and Modular Design

One of aluminum’s biggest advantages is modularity. You can easily add branches, outlets, or new drops without cutting, threading, or welding.

This flexibility makes aluminum piping the smart long-term choice for businesses planning future expansion.

Aluminum vs. Steel vs. Plastic Piping: Which Is Best?

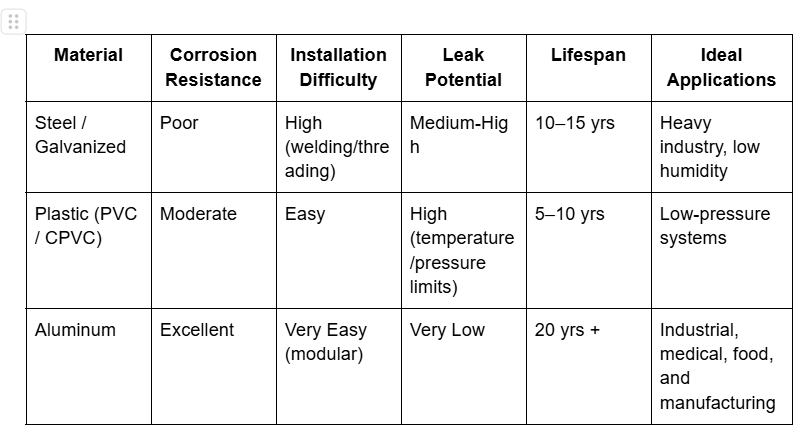

As shown, aluminum offers the best balance of durability, safety, and energy efficiency, especially for facilities that can’t afford leaks or contamination.

How IAS Texas Designs & Installs Leak-Free Piping Systems

IAS Texas employs a rigorous, systematic approach to ensure every compressed-air piping installation performs flawlessly, delivering optimal efficiency and long-term reliability for its clients. Their methodology goes beyond simply installing pipes; it encompasses a holistic view of the system, from initial assessment to ongoing support.

- Site Assessment: The process begins with a comprehensive site assessment. Experienced IAS engineers meticulously evaluate critical parameters such as existing compressor capacity, current and projected airflow demand, and the overall plant layout. This initial phase is crucial for understanding the unique operational requirements and physical constraints of each facility, ensuring the subsequent design is perfectly tailored to the client's needs. Factors like potential future expansion, environmental conditions, and specific industry regulations are also considered at this stage.

- System Design: Following the assessment, a detailed system design is developed using advanced CAD-based software. This sophisticated approach allows IAS to create a precise layout that minimizes pressure drop across the entire network, a key factor in optimizing energy efficiency and reducing operational costs. The design also proactively addresses potential future expansion issues, incorporating flexibility and scalability to accommodate growth without significant overhauls. Every aspect, from pipe routing and sizing to the placement of critical components, is carefully planned to ensure maximum performance and accessibility.

- Installation & Testing: Once the design is finalized, certified IAS technicians execute the installation. They specialize in the precise installation of high-quality aluminum lines, ensuring all fittings and supports are correctly applied to prevent leaks and maintain structural integrity. The use of aluminum is a deliberate choice, leveraging its lightweight, corrosion-resistant properties for superior long-term performance. Every connection is meticulously made, adhering to the highest industry standards to guarantee a robust, leak-free system.

- Performance Verification: Before the system is officially handed over to the client, a stringent performance verification process is conducted. This includes comprehensive pressure testing and leak testing of the entire network. These rigorous checks are essential to confirm that the system meets all design specifications and operates at peak efficiency, free from any air loss. Any discrepancies are immediately addressed and rectified, ensuring the client receives a fully operational and optimized compressed-air system.

- Maintenance & Support: IAS Texas's commitment to client satisfaction extends beyond installation. They offer optional service contracts and periodic audits to ensure the ongoing performance and longevity of the compressed-air system. These proactive maintenance programs help prevent potential issues, maintain system efficiency, and extend the lifespan of the investment. Regular inspections, filter changes, and performance checks are all part of a comprehensive support package designed to give clients peace of mind.

Furthermore, IAS recognizes that a truly efficient compressed-air system requires more than just piping. They seamlessly integrate complementary equipment such as advanced air dryers and filters. This integration is vital for maintaining system purity by removing moisture, oil, and particulates, which can otherwise compromise the integrity of downstream equipment and product quality. By ensuring a clean and dry air supply, IAS helps clients achieve superior operational efficiency and extend the life of their pneumatic tools and machinery.

Energy Efficiency & ROI of Aluminum Piping

While the upfront cost of aluminum piping is slightly higher than black iron, the

total cost of ownership is significantly lower.

Between energy savings, reduced leaks, and minimal maintenance, most facilities achieve ROI in 12–24 months.

According to the U.S. Department of Energy, reducing leaks by 20 % can cut total compressed-air energy consumption by 10 – 15 %. Paired with IAS’s leak-detection services, aluminum piping quickly becomes an investment that pays for itself.

Common Applications Across Industries

IAS specializes in the installation of advanced aluminum air systems, catering to a wide array of industries throughout Texas. Our expertise ensures that each system is precisely engineered to meet the unique demands and operational requirements of various sectors.

- Manufacturing Plants: In manufacturing environments, aluminum compressed-air piping is crucial for supporting critical operations. It seamlessly integrates with assembly lines, providing reliable air for pneumatic tools and advanced CNC machinery, thereby ensuring smooth and efficient production processes.

- Automotive and Body Shops: These facilities heavily rely on clean, consistent compressed air for a multitude of tasks. Our systems are vital for powering paint booths, enabling precise and high-quality finishes, as well as operating lifts and various air tools essential for repair and maintenance work.

- Food & Beverage Facilities: Maintaining stringent hygiene standards is paramount in the food and beverage industry. Aluminum air systems deliver clean, oil-free air distribution, crucial for preventing contamination and ensuring product integrity throughout processing and packaging.

- Hospitals & Laboratories: For medical and scientific applications, the highest quality of air is non-negotiable. IAS installs ISO-compliant medical air systems, providing ultra-clean, filtered air essential for critical medical equipment, patient care, and sensitive laboratory procedures.

- Commercial Buildings: Within commercial settings, aluminum piping supports a variety of essential functions. It is integral to maintenance shops for powering tools and equipment, and plays a key role in energy systems, contributing to the efficient operation of building infrastructure.

Regardless of the project's scale or complexity, IAS engineers are dedicated to designing each aluminum compressed-air system layout with a focus on maximum flow efficiency and long-term reliability. This meticulous approach guarantees optimal performance, reduced energy consumption, and sustained operational integrity for all our clients.

Frequently Asked Questions

1. Can aluminum pipe be used for compressed air?

Absolutely. Aluminum piping is one of the best materials for compressed air systems, offering exceptional durability, leak resistance, and clean airflow. Unlike traditional steel or PVC, aluminum won’t corrode or contaminate your air supply.

At Industrial Air Services Texas (IAS), we specialize in designing and installing aluminum compressed air systems that meet industrial standards for performance and safety. Our installations are engineered for long-term reliability, low maintenance, and maximum energy efficiency.

2. What is the best pipe for compressed air lines?

For most industrial and commercial applications, aluminum piping is the top choice. It combines the strength of metal with the flexibility of modular design, ensuring faster installation and cleaner air delivery.

IAS Texas exclusively recommends and installs premium-grade aluminum piping systems because they minimize pressure drop, prevent leaks, and improve overall compressor performance. Whether it’s for manufacturing, medical, or food production, our team ensures every system delivers consistent, high-quality airflow.

3. Is PEX ok for compressed air?

While PEX tubing is affordable and easy to install, it’s not designed or certified for high-pressure compressed air applications. Over time, PEX can degrade or rupture under continuous air pressure, posing a safety risk.

IAS Texas does not recommend PEX for compressed air systems. Instead, we provide professional aluminum air piping solutions that are tested for up to 232 PSI (16 bar) and backed by our expert installation and leak testing process. This ensures safe, efficient, and long-lasting operation for your facility.

Cleaner, Safer, More Efficient Air Systems

Choosing aluminum compressed-air piping isn’t just an upgrade; it’s a strategic move toward better efficiency, reliability, and air quality.

Whether you’re building a new plant or retrofitting an existing system, IAS Texas provides turnkey aluminum piping design, installation, and maintenance to keep your compressed-air system running at peak performance.

Ready to upgrade your air lines?

Contact Industrial Air Services Texas today for a site assessment or custom quote.