How Variable-Speed Air Compressors Unlock Significant Energy Savings: When, Why & How Much You Can Save

Powering Texas Industries Smarter, Not Harder

In industrial operations, compressed air is often referred to as the fourth utility, alongside electricity, gas, and water. However, unlike these other utilities, compressed air systems frequently operate with significant inefficiencies that can quietly drain thousands of dollars in energy costs. The

U.S. Department of Energy (DOE) estimates that compressed air systems can consume up to 30% of a facility’s total energy use. A substantial portion of this energy waste stems from the common practice of running traditional air compressors at full load, even when the actual air demand is much lower. This leads to wasted electricity, increased wear and tear, and higher operational expenses.

This is precisely where Variable Speed Drive (VSD) air compressors demonstrate their immense value. These intelligent and sophisticated systems are engineered to automatically adjust their motor speed in direct response to the facility's real-time air demand. By dynamically matching output to demand, VSD compressors drastically reduce power usage. Instead of operating at a constant, maximum capacity, they scale their performance up or down, ensuring that only the necessary amount of energy is consumed. This not only leads to substantial energy savings but also minimizes the mechanical stress on components, extending the lifespan of the equipment and reducing maintenance requirements.

We are committed to helping facilities across Texas achieve greater operational efficiency and cost savings. We specialize in the assessment, design, and implementation of energy-efficient VSD compressor systems. Our expertise allows us to deliver solutions that not only provide higher performance and reliability but also result in significantly lower operating costs and a faster return on investment. By upgrading to VSD technology with IAS, businesses can transform their compressed air systems from a hidden cost center into a powerful asset for sustainable and economical operations.

What Is a Variable-Speed Air Compressor?

A Variable-Speed Drive (VSD) compressor, often simply referred to as a variable-speed compressor, represents a significant advancement in air compression technology. Its core innovation lies in the use of an inverter-controlled motor that dynamically adjusts its speed in real-time, precisely matching the system’s air demand. This intelligent adaptation stands in stark contrast to traditional compressor designs. In a conventional fixed-speed compressor, the motor operates at its full Revolutions.

Per Minute (RPM) until the pre-set pressure is achieved within the system. Once this pressure threshold is met, the motor either completely stops or enters an "unloaded" state, where it continues to run but without actively compressing air. This cyclical pattern of constant starting and stopping, or running unloaded, leads to several inefficiencies. Energy is wasted during the acceleration phase of each start-up, and the repeated on-off cycles inflict considerable mechanical stress on the compressor components, ultimately contributing to increased wear and tear and potentially shorter equipment lifespan.

Conversely, a VSD compressor offers a more sophisticated and energy-efficient approach:

- Slows down when demand is low: When the demand for compressed air decreases, the VSD compressor's motor seamlessly reduces its speed. This means it only generates the exact amount of air required, eliminating the wasteful operation inherent in fixed-speed models during periods of low demand.

- Speeds up when demand increases: As the air demand rises, the VSD compressor's motor intelligently accelerates to produce the necessary volume of compressed air. This responsiveness ensures that the system always has an adequate supply without overproducing.

- Maintains consistent system pressure: One of the key benefits of this dynamic speed adjustment is the ability to maintain a remarkably consistent system pressure. Unlike fixed-speed compressors that experience pressure fluctuations as they cycle on and off, VSD compressors provide a stable and reliable air supply, which is crucial for many industrial processes.

This straightforward yet highly effective adjustment mechanism can translate into substantial energy savings, typically ranging from 25% to 50%. The actual amount of savings achieved is dependent on several factors, including the specific application of the compressor, the variability of the air demand throughout its operational cycle, and the overall usage pattern within the facility. Industries with fluctuating air demands, such as manufacturing plants with varying production shifts or facilities using air tools intermittently, stand to benefit most from the efficiency of a VSD compressor.

How Variable Speed Compressors Save Energy

Here’s why VSD compressors are game changers for operational efficiency:

1. Reduced Power Consumption

When your facility’s air demand drops, a fixed-speed unit keeps spinning, wasting electricity.

A VSD unit adjusts its RPMs dynamically, reducing power draw by as much as 35%, according to DOE studies.

2. Lower Heat Generation

Because the motor isn’t constantly running at full capacity, less heat builds up in the system. This means longer component life and reduced cooling costs.

3. Smooth Startup (No Power Spikes)

Fixed-speed compressors cause large inrush currents at startup, sometimes up to 6x full-load amps. VSD compressors start gradually, eliminating these spikes, which helps facilities maintain stable voltage and lower peak demand charges on utility bills.

4. Consistent Pressure = Better Performance

VSD systems maintain tighter pressure bands (±2 PSI), meaning your tools and equipment operate more efficiently with fewer fluctuations.

IAS installs advanced control systems that automatically optimize compressor speed, reducing energy waste without sacrificing performance.

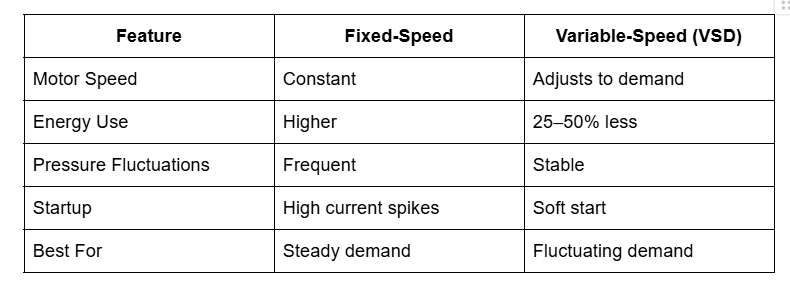

Fixed-Speed vs. Variable-Speed Compressors

IAS Texas helps clients determine which type fits best; sometimes the ideal solution involves a hybrid system (one VSD unit + one base-load fixed-speed unit).

Real-World Example: Cutting Costs with Smart Air

A manufacturing client in Dallas partnered with IAS Texas to replace two aging fixed-speed compressors with a 60 HP VSD rotary screw unit.

After a system redesign and leak inspection, the results were remarkable:

- Energy consumption reduced by 32%

- Annual savings exceeded $7,800

- Payback period: 18 months

- Noise reduction: 10 decibels quieter operation

Beyond the energy benefits, the client experienced more consistent air pressure and fewer maintenance interruptions, keeping production lines running smoothly.

When Should You Choose a Variable-Speed Compressor?

A VSD system is ideal if your facility experiences:

- Fluctuating air demand throughout the day or week

- Variable production schedules or shift changes

- Seasonal workload changes

- Unstable system pressure or air leaks

VSD compressors may not be necessary for operations with constant full-load demand, but for most Texas facilities, variable-speed technology delivers measurable ROI.

IAS engineers conduct energy audits and flow analysis to determine whether your operation will benefit most from a VSD upgrade.

How IAS Texas Delivers Energy-Efficient Solutions

When it comes to compressed-air efficiency, IAS takes a data-driven, holistic approach:

- Energy Audit & Flow Measurement: identify baseline performance and usage patterns.

- System Design Optimization: recommend the right VSD model, size, and controls.

- Installation & Commissioning: integrate dryers, filters, and aluminum piping systems for maximum efficiency.

- Performance Monitoring: provide periodic maintenance and post-install analysis to track savings.

Every IAS solution is backed by leading manufacturers, certified technicians, and ongoing support, ensuring your investment delivers lasting performance.

The ROI of Going Variable-Speed

While a VSD compressor can cost 10–15% more upfront, it often pays for itself within 1–2 years through energy savings alone.

With lower maintenance costs and extended equipment life, the total ROI can exceed 150% within three years.

Quick Math Example: A 50 HP fixed-speed compressor may cost $20,000/year in energy.

Switching to a VSD unit can save

$5,000–$7,000 annually, plus reduce wear and tear.

Partner with IAS Texas for Smarter Air Solutions

Whether you’re building a new plant or upgrading an old system, IAS Texas offers turnkey air solutions that combine:

- High-efficiency VSD compressors

- Leak-free aluminum piping

- Air dryers and filters for clean, dry air

- Professional service and maintenance

With IAS, you get more than equipment; you get a strategic energy partner committed to reducing your operating costs while boosting performance.

Control the Speed, Control the Cost

Variable-speed air compressors are more than just a trend — they’re the future of industrial energy efficiency. By adapting to real-time demand, these systems deliver consistent performance, cleaner air, and lower utility costs.

Partnering with Industrial Air Services Texas means you’re choosing more than a supplier; you’re choosing a long-term partner in operational excellence.

Ready to see the savings?

Book your free VSD system consultation and let IAS design a smarter, more efficient air solution for your facility.

Follow us on LinkedIn or Instagram for more tips and updates!

Frequently Asked Questions

1. What is a variable speed compressor?

A variable-speed compressor, also known as a VSD (Variable Speed Drive) compressor, automatically adjusts its motor speed according to the amount of air your system require. Instead of constantly running at full capacity, it speeds up or slows down to match demand, saving energy, reducing wear, and maintaining stable air pressure.

AtIndustrial Air Services Texas (IAS), we specialize in designing and installing variable-speed air systems for industrial, medical, and commercial facilities. Our engineers customize each setup to deliver consistent airflow, reduce electricity costs, and extend compressor life. With IAS, you get the perfect balance of power, precision, and performance, engineered for your specific application.

2. Which is better, a fixed or a variable AC compressor?

It depends on your air demand, but in most cases, a variable-speed (VSD) compressor is far superior to a fixed-speed model.

Fixed compressors run at full power even when demand is low, wasting energy and increasing wear. A variable-speed compressor, on the other hand, modulates output to match your air needs, reducing energy use by up to 35–50% while maintaining consistent pressure.

That’s why IAS Texas recommends VSD systems for facilities with fluctuating air demand. Our experts can assess your operations and design a hybrid setup (combining fixed and variable-speed units) for maximum efficiency and reliability. With IAS, you’re not just getting equipment, you’re getting an energy-optimized system that grows with your business.

3. Is it cheaper to run a mini split or central AC?

When it comes to HVAC-style compressed air systems, efficiency depends on how well your system matches demand. Mini-split-type systems (VSD compressors) adjust speed to save power during light usage, whereas central systems (fixed-speed compressors) often run continuously, consuming more energy.

In most facilities, variable-speed or modular air systems, similar in principle to mini-split ACs, are cheaper to operate and provide better control.

IAS Texas designs customized air solutions that use variable-speed technology to minimize energy waste, stabilize pressure, and extend equipment lifespan. Whether you operate a small workshop or a large industrial plant, IAS ensures your system is built for efficiency and long-term savings.