How to Choose the Right Blower System for Your Manufacturing Plant

In manufacturing, air isn’t just air; it’s the unseen powerhouse that keeps your operations moving. Whether you’re running pneumatic systems, material conveying, or wastewater treatment, the right blower system determines your plant’s efficiency, energy costs, and equipment lifespan.

At Industrial Air Services Texas (IAS), we assist manufacturers across Texas in designing, installing, and maintaining industrial blower systems that deliver consistent performance and reliability. Here’s how to choose the right one for your facility. In the intricate world of manufacturing, air is far more than just an atmospheric element; it is the unseen, yet critical, powerhouse that consistently fuels and sustains your entire operational ecosystem. Its proper management and application are paramount, impacting everything from the precision of your machinery to the purity of your products.

Whether your plant relies on the delicate control of pneumatic systems, the efficient transfer of materials through conveying processes, or the vital aeration required for wastewater treatment, the selection and implementation of the right blower system are fundamental. This crucial decision directly influences your plant’s overall efficiency, dictates your energy consumption and associated costs, and significantly impacts the longevity and reliable performance of your invaluable equipment.

Choosing the ideal blower system for your facility is a strategic decision that demands careful consideration of various factors. Here's a detailed guide to help you navigate this essential process:

Understanding the Role of Blower Systems in Manufacturing

Industrial blower systems are indispensable components in a wide array of manufacturing processes, serving as the lungs of many operations by facilitating the movement of large volumes of air or gas. Their applications are diverse and critical, ranging from essential cooling and efficient drying to vital aeration and effective dust control. These systems are not merely moving air; they are integral to maintaining optimal operating conditions, ensuring product quality, and safeguarding the health and safety of personnel.

However, the effectiveness of a blower system is entirely dependent on its proper selection and integration. A common and detrimental mistake in manufacturing environments is the deployment of a system that is either undersized for the required task or poorly matched to the specific demands of the application. The ramifications of such an oversight can be significant and far-reaching, leading to a cascade of operational inefficiencies and increased costs.

A poorly chosen or undersized blower system can directly lead to:

1. Pressure Instability

This manifests as erratic or insufficient airflow, which can severely disrupt processes that rely on consistent pressure, such as pneumatic conveying, combustion air supply, or even maintaining cleanroom conditions. Inconsistent pressure can lead to product defects, extended processing times, and a general lack of control over critical parameters.

2. Energy Waste

An improperly sized blower will invariably consume more energy than necessary. If it's too small, it will have to work harder and longer to achieve the desired effect, leading to higher motor speeds and increased power consumption. Conversely, an oversized blower, while seemingly capable, can still waste energy by operating inefficiently outside its optimal performance curve or by being subjected to unnecessary throttling. This translates directly into elevated utility bills and a larger carbon footprint.

3. Excessive Noise and Vibration

These are not just nuisances; they are indicators of mechanical stress and inefficiency. High levels of noise can contribute to an unsafe working environment, potentially leading to hearing damage for employees and reducing overall productivity. Excessive vibration can damage the blower itself, its supporting structures, and even adjacent equipment, leading to premature wear and failure. These issues often arise from imbalances, improper mounting, or the system operating outside its design parameters.

4. Premature Equipment Failure

This is the most severe consequence, directly impacting operational uptime and maintenance costs. When a blower system is constantly straining to meet demands it wasn't designed for, or is subjected to undue stress from vibration and instability, its lifespan is significantly shortened. This can result in costly repairs, frequent breakdowns, and the need for early replacement of expensive equipment, all of which disrupt production schedules and impact profitability.

Therefore, a thorough understanding of the specific application requirements, including air volume, pressure needs, temperature, and the nature of the gas or particles being moved, is paramount. Investing in the correct blower system from the outset is not merely a purchase; it's a strategic decision that underpins operational efficiency, energy conservation, worker safety, and the long-term economic viability of the manufacturing plant.

Explore our

Blower Systems and Vacuum Solutions to see how IAS customizes air movement solutions for Texas manufacturers.

This is paragraph text. Click it or hit the Manage Text button to change the font, color, size, format, and more. To set up site-wide paragraph and title styles, go to Site Theme.

Key Factors to Consider When Choosing a Blower System

1. Airflow Capacity and Pressure Requirements

Determine your required CFM (Cubic Feet per Minute) and PSI based on production lines, equipment, and process load. Oversizing can waste energy, while undersizing leads to performance bottlenecks.

2. Energy Efficiency and Power Consumption

Energy accounts for nearly 70% of the total lifecycle cost of a blower. IAS recommends VFD (Variable Frequency Drive) blowers for facilities that need variable airflow, helping you reduce power costs by up to 30–40% (source: DOE, 2024 report on industrial efficiency)

3. Noise and Environmental Control

In Texas plants, where OSHA noise limits apply, choosing a blower with sound-insulated enclosures or installing vibration dampeners can maintain worker comfort and compliance.

4. Maintenance and Reliability

IAS provides preventive maintenance programs designed to extend blower life through regular inspections, lubrication schedules, and vibration monitoring.

Energy-Efficient Blower Design and Layout

Achieving maximum energy efficiency in a manufacturing plant's blower system hinges on meticulous design and layout. IAS engineers employ a comprehensive approach, meticulously evaluating every component to minimize energy loss and enhance operational performance.

Key Design Considerations:

- Duct Design: The geometry and material of ductwork significantly impact airflow. Smooth, adequately sized ducts with minimal changes in direction are crucial for reducing friction and pressure drops.

- Pipe Diameter: The Correct pipe diameter is essential. Pipes that are too narrow increase air velocity and friction, leading to higher pressure drops and greater energy consumption. Conversely, overly wide pipes can lead to inefficient airflow and material settling.

- Air Distribution Patterns: Even and consistent air distribution is vital for process efficiency. Engineers carefully design the layout of diffusers and nozzles to ensure optimal coverage and prevent dead zones or excessive turbulence.

Pro Design Tip: Optimizing Layout for Reduced Resistance

A well-planned, straight, and balanced layout with the shortest possible turns can significantly reduce system resistance by up to

15%. This optimization directly translates to improved airflow, reduced energy consumption, and a noticeable decrease in operational noise levels, creating a more conducive working environment.

Turnkey Design-Build Solutions for Seamless Integration:

IAS distinguishes itself by offering

turnkey design-build solutions. This comprehensive approach means that all aspects of the process air management system are designed, integrated, and implemented by a single provider. This includes the seamless integration of blowers with essential auxiliary equipment, such as:

- Dryers: For applications requiring controlled moisture levels in the air.

- Filters: To ensure the cleanliness of the process air, protecting equipment and product quality.

- Controllers: Advanced control systems optimize blower operation, allowing for precise adjustments to airflow and pressure based on real-time process demands, further enhancing energy efficiency.

By providing a complete, integrated solution, IAS ensures optimal performance, reliability, and energy efficiency for the entire manufacturing process.

Why Texas Manufacturers Choose IAS

- 30+ years of experience in industrial air movement solutions

- Certified technicians for installation, repair, and balancing

- Access to top-tier blower brands and energy-efficient technologies

- 24/7 emergency service and maintenance support

Learn more about our custom blower installations for Texas manufacturers. Contact us now!

Unlock Peak Performance with Industrial Air Systems Texas

At Industrial Air Systems Texas, we understand the unique demands of modern manufacturing. That's why we offer a comprehensive approach to blower system solutions, designed to deliver tangible benefits for your business.

Free Assessment & Expert Consultation

Don't guess when it comes to your plant's critical systems. Contact Industrial Air Systems Texas today for a no-obligation, free assessment of your current airflow and a personalized blower system consultation. Our experienced engineers will meticulously evaluate your facility, identify areas for improvement, and recommend the most effective strategies.

Custom-Engineered Solutions for Unmatched Efficiency

Our team of experts doesn't believe in one-size-fits-all. We pride ourselves on designing custom-engineered blower solutions that are perfectly tailored to your plant's specific needs, size, and operational requirements. By leveraging cutting-edge technology and industry best practices, we create systems that are not only powerful but also incredibly energy-efficient.

Experience the Industrial Air Systems Texas Advantage:

- Boosted Productivity: Our optimized blower systems ensure consistent and powerful airflow, facilitating smoother processes and reducing downtime.

- Lower Energy Costs: By implementing highly efficient solutions, we help you significantly reduce your energy consumption, leading to substantial savings on your utility bills.

- Enhanced Operational Reliability: With robust and dependable systems, you can minimize maintenance issues and ensure uninterrupted operations.

- Improved Air Quality: Our solutions contribute to a healthier and safer working environment by effectively managing airborne contaminants and maintaining optimal ventilation.

- Expert Support from Start to Finish: From initial consultation and design to installation and ongoing maintenance, our dedicated team provides unparalleled support every step of the way.

Invest in the future of your manufacturing plant. Let Industrial Air Systems Texas be your partner in achieving unparalleled efficiency, productivity, and cost savings.

Contact Industrial Air Systems Texas today to schedule your free assessment and discover how our custom blower solutions can transform your operations.

Frequently Asked Questions (FAQs)

1. What is a blower system?

A blower system is an industrial machine designed to move air or gas through ducts, pipes, or processing lines. It’s essential in applications like manufacturing, wastewater treatment, and pneumatic conveying. At Industrial Air Systems Texas (IAS Texas), we provide custom-engineered blower systems that optimize airflow, improve process efficiency, and meet the strictest industrial standards. Learn more at iastx.com.

2. What are the three categories of blower motors?

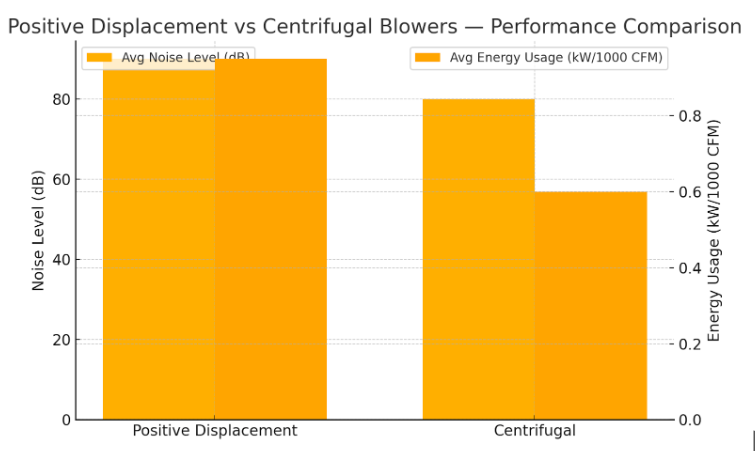

Blower motors generally fall into positive displacement, centrifugal, and regenerative types.

- Positive displacement blowers deliver a constant air volume regardless of pressure changes.

- Centrifugal blowers are ideal for high-flow, lower-pressure applications.

- Regenerative blowers provide clean, oil-free air for lighter applications.

At IAS Texas, we supply and service ELGi, Republic, and Becker blowers: all trusted for performance, durability, and energy efficiency.

3. How much does a blower make?

Blower systems can produce anywhere from a few hundred to hundreds of thousands of cubic feet per minute (CFM), depending on size and application. IAS Texas can assess your plant’s needs and recommend the right capacity and configuration to keep your production efficient while minimizing energy costs.

Our experts also help you balance performance with power consumption for long-term savings.

4. What is the difference between a fan and a blower industrial?

Both fans and blowers move air, but their pressure ratios and applications differ.

- Fans move large volumes of air at low pressure.

- Blowers move smaller volumes of air at higher pressure, perfect for manufacturing processes that require controlled air movement.

IAS Texas specializes in

industrial-grade blowers engineered for precision airflow, process reliability, and compliance with

ASME and ISO standards.

5. What is the most efficient blower motor?

The most efficient blower motors are

variable frequency drive (VFD) blowers, which adjust motor speed based on demand, helping facilities

save up to 30–40% on energy costs.

IAS Texas recommends

VFD-equipped ELGi and Republic blowers for operations that require variable airflow without sacrificing efficiency. Our team provides

end-to-end installation, calibration, and maintenance, ensuring peak energy performance.